The challenge

One of the world’s leading manufacturer of tires and rubber products, had the goal of creating an industrial maintenance solution based on augmented reality in order to:

- have quick access to remote knowledge;

- deliver strategic information to frontline workers, right where an d when they need it;

- minimize downtime;

- reduce costs.

The Solution

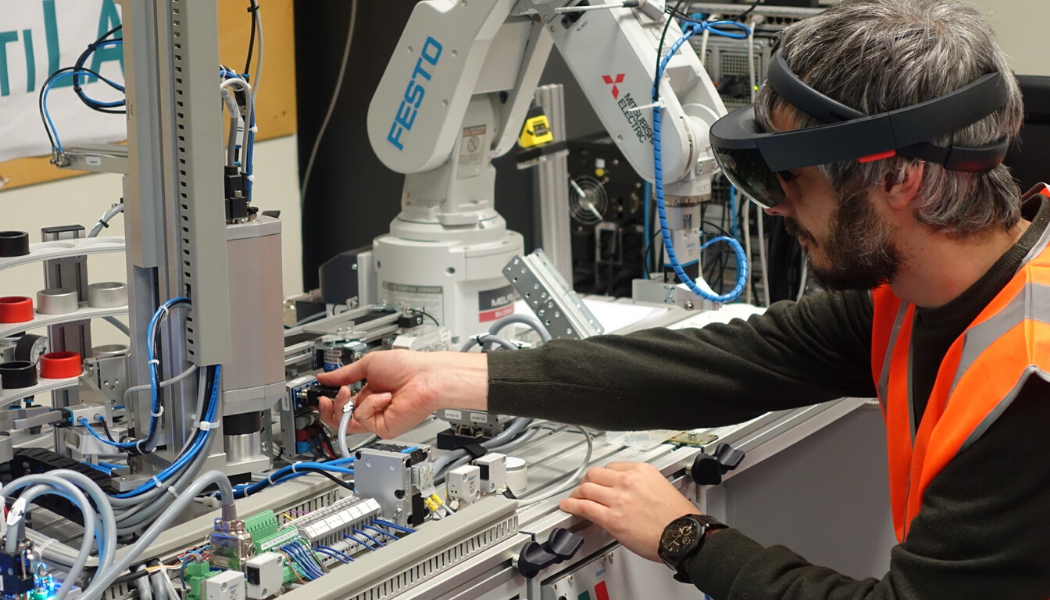

The plant in the South of Italy implemented Scotty Expert with Augmented Reality (AR) to pursue a new and remote training model for operators and maintenance technicians.

The combination of AR with 3D models offers interesting augmented reality experiences, making workers more efficient and keeping them safe.

Advanced machine vision features bring products to life and engage frontline workers with 3D content and IoT data.

The platform combines advanced augmented reality-based collaboration tools with real-time video communications to connect a field technicians with experts. The latter can draw holographic annotations that precisely adhere to real- world 3D physical objects, enabling technicians to follow the process step by step.

The Benefits

The implemented solution implemented allows users to view every type of experience on their favorite mobile devices, 2D and 3D wearables.

In terms of business benefits the solution provides:

- Increased workforce productivity and efficiency;

- Faster and more cost-effective new worker training;

- Lower cost of downtime costs, scrap and rework;

- Improved safety and compliance adherence;

- SLA meeting and better customer satisfaction;

- Lower repeat visit costs and better first-time-fix rates.